In the fourth part of this series following EVolution Hybrid, a project integrating a traditional semi truck with a combustion engine with a EV battery and electric vehicle technology we get an update on the engine features, roadblocks and successes.

In this exclusive interview with Levi Perkins, Perkins Electric Innovation, and Kenley Nebeker, TrainND Northwest, the two discuss how EVolution Hybrid is ready to take on these traditional challenges, plus a couple anticipated ones too.

In Part Three the challenge is towing and range anxiety.

“If we have a greater amount of weight that we are towing or resistance whether it be a vertical incline or bad roads or a low tire, just things that will impact how much power we are using and increase the amount of amperage by the motor, and that would consume the battery quicker.”

Towing creates conversations about torque as well.

“The electric motors we are using they can build what we call Peak Torque at a really low if not zero RPM,” Perkins said. “This is different from a reciprocating piston where your peak torque could be at a specific RPM usually in the RPM range.”

The interview also discussed tires and how many electric vehicles have specific tires for the vehicle and if someone put new tires on, it impacts how far you can drive. So does temperature.

“An individual going to see his son on Christmas on the east coast was set to drive 200 miles in the below freezing temperature after he hit the SuperCharge Station close to his house,” Perkins said. “When he left his garage the Tesla battery was warm enough to start and drive, only when he got to the charge station and at that point the battery has discharged some but it’s cool enough it will not allow him to charge.”

This transitioned into one of the biggest issues right now for the EV Transition is “Range Anxiety”. Nebeker has had first hand experience and says it is a real thing.

“I experienced range anxiety first hand and absolutely it is real,” Nebeker said. “That question of am I going to get where I need to get is a real worry with range anxiety. With an internal combustion engine with gas motors, you know you have until empty then you have to fill it up. It’s a consistent draw versus unpredictability really.”

In Part Two, the two talked about time and money.

When it comes to life, time is money. In transportation it’s time and weight that equal money. Well in the world of EV Transportation, it’s time, weight and temperature that mean money.

In Part One, the two gave an overview of project EVolution Hybrid, which is integrating an electric battery into a traditional combustion engine while maintaining the classic trucking look. With maybe a hint of flare or contemporary fashions.

“One of the things we looked at with the EVolution Hybrid is the future of the transportation and trucking industry,” Kenley Nebeker, executive director, TrainND Northwest said. “We are really trying to find a way to expose our students and the community to the potential that lies within the electric truck, or in this case a hybrid truck. I’ve never been a believer in all-one-way or another.”

Nebeker is referring to an all EV solution or an all fossil fuel solution. Nebeker believes this project will shine a light on how a “marriage” between the two concepts will ultimately become a viable solution to an energy transition.

“One important part of this project is the look,” Nebeker said. “I like that traditional Americana semi truck look and understand that still connects with the public too.”

One of the ways the electric combustion collaboration can occur is weight. According to Perkins, the weight of fuel, the batteries and cargo are factors when determining your bottom line in business.

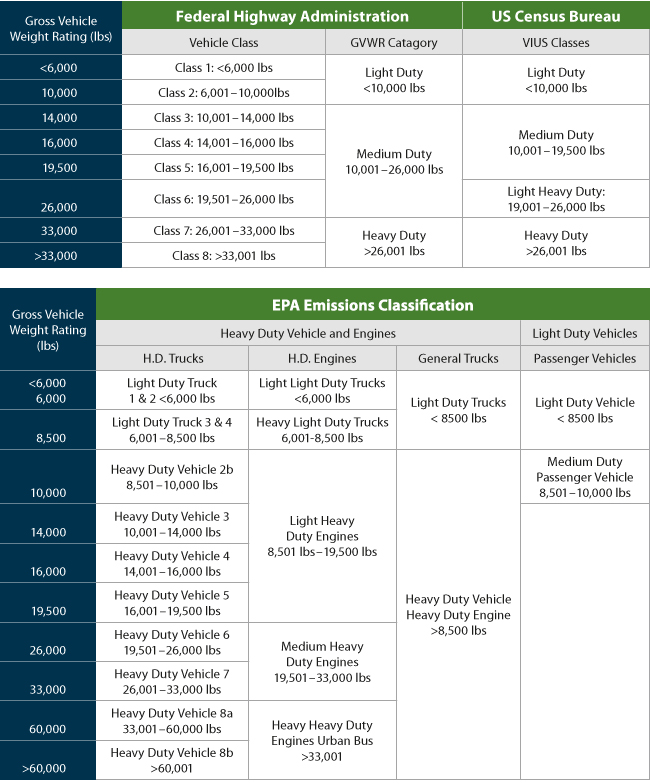

“Most Class A trucks vary as there are different models from the manufacturers, but there’s a lot that is similar” Perkins said. “The less a truck can weigh, the more freight you can haul and essentially, generate higher revenues because of it.”

For fleets, this could have significant savings. Perkins dives into the details of sleeper cabs, drop steer axles and other accessories when discussing the weight and revenues in trucking. All these additional details matter when discussing electric batteries and transition.

“Most electric trucks are going to be in the 400-600 kilowatt hour range. Tesla just released a 1000 kilowatt hour battery,” Perkins said. “But interestingly enough in the past three years the battery technology has allowed us to have reductions in weight but still, it is over 10,000 pounds in battery weight.”

The interview also discussed the difference between fuel weight and battery weight. Which would save money in the long haul? Host Jason Spiess cited an example of an interview with Keri Frank, CEO, Comply365, and her integration of iPads in aviation.

“Before iPads, the industry had a 50-plus-pound black metal box that contained procedure papers required by law,” Spiess said. “After Keri Frank got the industry to transition those papers to an iPad, not only did they see an immediate impact by not printing new sheets every time a new code was issued. But the real savings they saw was over a year in fuel savings. The weight over time was nickels turning into dollars.”

Both Nebeker and Perkins agreed with the sustainable savings and how trucking companies will see similar results.

Another area of change or transition EVoltion Hybrid will see is jobs. Nebeker is anticipating changes with mechanics, IT and other areas of trucking and transportation, and is in constant contact with the supply chain and supporting cast.

Here are some supporting interviews for EVoltion Hybrid and the community of Williston, ND.

Williston’s Wenko Says Economic Development Getting More Diverse

Williston Mayor Talks About The Bakken’s Continued Community Growth

Bakken Small Businesses Staying Busy

Bakken Boom Created An Astounding Educational Opportunity For Williston State Students

The project is scheduled to take 9-12 months, depending on the supply chain, according to Nebeker.

Interviews are sponsored in part by TrainND Northwest – It’s a competitive world. Train for it.

About The Crude Life

Jason Spiess

All right, let’s go to the zoom line where we’ve got Kenley never occur with train. Nd Northwest as well as Levi Perkins with Perkins Electric innovation. This is our update here on the Evolution E V evolution hybrid. It’s a project that Train N D North Dakota and Perkins Electric Innovation are doing in partnership with the United States Commerce Department, is that correct? It’s the federal one, Kenley.

Kenley Nebeker

Yeah, federal federal governments. Uh, this is ultimately being paid for at least 80% paid for by, by a grant from the federal, uh, from, from the Federal Department of Commerce. Yeah.

Jason Spiess

So folks, if you want to go to the crude life dot com or e S G you dot org, we have the following links with the history of this. So, if you want to track last month, I think we did some different weights and some different, uh, torque involved with the evolution that’s happening, the evolution evolution of the hybrid. But folks, what we’re talking about here is in one of those traditional semis that you see, get on a great big convoy semi.

Uh, and we’re gonna try to figure out a way to grab an E. V motor into a combustion motor, combine them together and get more than two miles a gallon Kenley. How are you doing today? Levi, how you doing today? And let’s talk about the motor today and there’s a couple different options. So let’s start off with laying the groundwork Kenley. What kind of motors are we looking at here? Yeah, we’re first

Kenley Nebeker

of all. Good morning and thanks for having us on and we’re excited about the, where the project is going, we’re having a lot of conversations about uh, design and what we wanna do. And one of the big conversations has definitely been around uh, the electric motor and which direction we wanna go currently on the market, there’s, there’s multiple options.

Um, you can kind of go with, with uh, with what’s been really, seems to be real popular here in the United States as we see these electric vehicles, fully electric vehicles, blue forward, which is the idea of of having multiple small motors inside of an axle, uh, to drive the wheels. Um, and that seems to be a real popular uh, direction here in the United States with the electric vehicles with a fully electric semis, like the Tesla and whatnot.

The other option that, that you, that you really have, and there’s different divisions within those, those small motors within the axles. The other option that we’ve been exploring, and I think that Levi can, can kind of talk about this, but I think we’re leaning towards is having one big motor, electric motor that then drives a drive line that then drives, drives the, the axles.

And so, um, I think we’re, we’re excited to see and, and I think that this is a great conversation for us to have and, and kinda kinda share what, what we’re thinking and why we’re thinking it.

Jason Spiess

Alright, Levi talk a little bit about the different types of engines in the selection process that’s going into this.

Levi Perkins

Yeah, so, uh I think in the past a lot of the electric vehicles that we’ve seen on the market, whether it be a very small passenger vehicle, like a car or even a small utility pickup. A lot of times they’re gonna utilize a mo an electric motor and it could be like a permanent magnet type DC motor. Some of these are a C induction motors that they used, uh and some of them are brushed and some of them are brush list, but regardless, a lot of times we’re seeing that because these electric

motors that just inherent capabilities of them at zero rpm are just barely off of starting to turn, they can actually produce peak torque with no rpm. So you can, you it reduces the need for a gearbox at all and that’s kind of cool it several, you know, a lot of these electric vehicles, they don’t have any kind of gear reduction, some of them will have an overdrive, but a lot of them don’t because the motors can go from zero to like three or four or 5000 RPMs, which is similar to an

internal combustion, like a piston style engine, but they can build peak torque at very low if any rpm. So we’re just and right now on this, on the class eight truck side or maybe even like medium duty class five trucks, a lot of the Class five electric vehicles that have been on the market the last 10 years. They don’t have any gear box, they don’t have a gear reduction.

So it’s just a motor to a drive line to a rear axle and the rear axle oftentimes will have very a traditional gear ratio in it like a, you know, like on a pickup, you can have 3 55 to 1 gear ratio of 4, 10 gear ratio and essentially that’s just a 4 to 1 reduction in the ring gear to the axle shafts that the tires are bolted to. So we’re seeing a lot of these Class five medium duty van trucks that are electric or have been converted to electric, they don’t have a gearbox in them.

And, and that’s kind of exciting. It simplifies the drive train. So, in essence, instead of, and this is where it becomes very attractive to consumers, instead of having a reciprocating piston diesel engine. And then you’ve got all the complexity of the fuel side of it. And what type of, you know, you’ve got to get good ultra low sulfur diesel fuel and the filters and high pressure common rail injection systems and it needs to be turbocharged and a lot of them will have overhead

camshafts and, and then you’ve got to have a gearbox and it’s, it could be automated or not automated, it could be stick shift or automatic and then you then all of that is the engine has an after treatment system for the reduction of NOX and particulate matter and lots of complexity in that system. Whereas this other system is just a motor controller and batteries.

So it’s attractive in that regard. And and I think that there’s a lot of different directions you can go with the motor and hopefully today we get to talk a little bit about directions and ways that we can do it too. Even simplify the drive train more

Jason Spiess

when you’re looking at Tesla or one of these ion six or you know Audi has one too. Um What kind of motors do they have in comparison to what you’re talking about? Just for the average consumer.

Levi Perkins

Yeah that’s a great question. So what we’ll see on those a lot of times older electric vehicles that we saw in the nineties, a lot of those had 3 to 400 volts Dc to permanent magnet motors and they were D. C. Motors and some of them were even brushed DC motors, so there would be maintenance involved with them. And some of the early electric conversions that you could do to a gas vehicle to take the piston engine out and put an electric motor in.

They were actually brushed Dc motors. So these newer ones now what they’ve done and this is really smart if you think about the to simplify this, if you’ll think about the like the electric drill market right now 15 years ago we used to have these like 12 volt electric drills. They were really low power. They had brushed dc motors, they were really heavy.

They probably had nickel cadmium batteries. They didn’t have a lot of duty cycle really high, you know, minutes or hours of charge time. Just not convenient. People didn’t like them. But as things progressed, we went to to brush less motors or permanent magnet motors. Like if you think of Milwaukee or DeWalt or some of these, and then we went to a higher voltage, so we would see 16 volts a long time ago.

And then 18 and then 20 and then even 24 volts and some of them for a while. We had 28 volt flat systems, the same thing with the electric vehicle market. Now we’re seeing uh 600 volts is the standard. And we even have some vehicles that are running in the 800 volt range and some medium duty trucks and class eight trucks that are in the 800 volt range because we can potentially consume, we can extract more power, useful power out of a smaller battery pack.

It the voltage is higher and, and it’s dangerous. I mean, if people have ever told you that you can’t be killed by dc voltage, that’s a lie. It’s just the fact that our common dc voltages that we work around, or like 12 volts, 14 volts, 20 volts and they won’t kill you, you wouldn’t even feel that but I promised you 600 volts that could kill you. So it’s it’s a little bit more dangerous. But uh there’s a lot of energy density when we have voltage is higher in these battery packs.

And so what we’re seeing now to answer your question is passenger vehicles like the Tesla cars and Audi and some of these other ones that ford is produced and Gm they’ll be in the 600 to 700 volt range and they’ll be using permanent magnet motors and some of them are using a C induction motors to there really like a six phase induction motor and they’re very very efficient and they can produce a lot of power in a very small package. So hopefully that answers your question

Jason Spiess

well I think so. Is this gonna be something that uh you’re foreseeing somebody can plug in at their shop or at their at their business or are there gonna be charging stations for this? What type of um I guess charging capabilities do you foresee at the end of the day with this?

Levi Perkins

Yeah, that’s a great question, Jason. So one thing that Kinley and I have discussed is if you have an electric vehicle and let’s just say that you because Tesla is so popular and people seem to know a lot about them whether it be a Tesla, another passenger, light duty vehicle, like a passenger car. If it’s 600 volts D. C. You’ve got several options to charge from.

There’s a couple of different I. S. O. Connectors that you can use that are certified and they’re utilized throughout the world. Actually the International standards Organization is certified these as connectors similar to a wall connected that we use in our house. So you could charge electric vehicles off of 1 10 which would be a wall outlet in your house.

And if it was a larger battery pack like a 100 kilowatt hour pack, you probably would have a really long charge time because it’s only 100 and 20 volts. It’s a C. Voltage that needs to be converted to D. C. And you could have like a 12 or 14 hour charge time depending on the size of your battery pack. But if your house out say that you pulled into your garage and in your garage you had an outlet similar to what you have for your dryer or a larger appliance, like an oven that was 240 volts.

Well then it would reduce the charge time in half almost. And and then if you stepped it up even farther Jason you could charge if you wanted to you could put in a test of charging bank inside of your house that would if you had power available and had 480 bolts of single phase or even some of these places will have three phase power. Now you’re charging time is clear to nothing.

You could have a two hour charge time to go, you know, another 400 miles or 300 miles. So it all depends on what voltage is available at a charging place, but it could actually be charged off of 1 20 or 2 40 or 4 80. And then we’ve got some of these mega chargers to where you know, they’re actually utilizing really high voltage and high amperage to charge their car in like 30 minutes, you know, or less. Or if it was like an F 1 50 lightning or something like that, or Rivian electric truck.

So a lot of the larger tests of charging stations, depending on where they’re located, they could have really large amounts of power that are available. So you can charge quicker and the batteries are able to take a charge that passed. Some batteries aren’t lithium iron phosphate batteries can take a really fast charge high voltage because they’re set up in a bank of batteries, probably close to 600 volts or more. …

Jason Spiess

I was gonna ask you, is this gonna be a lithium based or is there some sort of super cold vault or what kind of rare earth minerals are we talking about behind this type of battery? …

Levi Perkins

That’s a great question. There’s there’s so many different battery technologies available right now. But for this project, probably the most proven and most readily available at this time is lithium iron phosphate or lipo. Like there’s, they’ve kind of coined like the life go for battery or lithium iron phosphate battery, there’s a lot of different ways.

I think you could kind of skin that cat to, there’s, there’s cylindrical cells that would be very similar to what Panasonic is produced for Tesla and what Panasonic’s are really large producer of lithium iron phosphate batteries for a plethora of devices, whether it’s cell phones or laptops or solar panel, battery banks or, or light duty or heavy vehicles.

So they, they use a cylindrical cell, there’s some hexagonal cells that we’ve seen come out of china that are not really that bad. But it’s, it’s a, it’s not a domestic product and before and and there there’s some, there’s a lot of really neat battery technologies that are emerging right now that they stand to be proven, you know, as far as overtime, but they seem to be really, really viable and that’s probably our largest hurdle that we’re up against is the more weight you pull

Jason and Kinley is aware of this, the more weight you’re pulling, the higher amount of amperage your vehicle will utilize and the more energy it will consume. So then what you need to do is you’ll have to add batteries. Well, when you add batteries, you add an extensive amount of weight. So then it’s just this, you know, you’ve got this teeter totter effect where you’re just gonna continue to add batteries, but you’ll add weight and it will consume more power to pull that much

weight. And so We came a long ways in the last 10 years and I hope hopefully we’re gonna go farther. But uh that’s kind of where we’re at right now. I mean you get to this point where 600 kilowatt hours of batteries on a semi truck, you could have eight or £10,000 worth of batteries depending on what type of heating and cooling system they have. You can have a lot of batteries on it to try to go 300 miles. And that, that’s really the biggest hurdle right there.

Jason Spiess

My understanding is that when these motors and batteries come to fruition, there is a lot less maintenance on them. Is that the case with this that you’re seeing too?

Levi Perkins

I think. So if if if the charge times and cycles would be similar to, you know, when cell phones and I don’t want to date us or date myself. But you know, the, I can think about in the late nineties when Nokia kind of had the brick phones and those had a different base of battery, they were not lithium, you know, most of those are nickel cadmium batteries, but they would kind of have what we could quote unquote a memory and people would say, well they have a battery memory and if you’ll

fully discharge them and then fully cycle them, you’ll get the most amount of use out of those. And usually it was less than two years. Well, because of lithium iron phosphate, a lot of the specialists have said they don’t have a memory like that, but it’s it’s not really true. They’re damaged by high heat and low and low temperatures. So anything under 20° is really harmful on them to discharge them or charge them.

And then anything over about 80° actually is harmful to them. So, and some people said they can withstand 100 220 degrees they can, but you’ll see less charge cycles at them. But we also know that the battery pack, if you have a battery pack that they can range in price anywhere 100 kilowatt hours at one point in time we thought, okay, that would be like a $20,000 Battery pack and we’ve seen it as low as 12,000.

But when we’ve seen him as high as 50,000, I mean, they’re just, I read an article one time, the guy, I talked about how he just, he’s like, I don’t want to replace the battery pack in my protest. It costs more than the car cost to replace 100 kilowatt hour pack or an 80 kilowatt hour pack. And that’s something to think about. But I think that to answer your question, The battery pack should last somewhere between 5-7 years and and, And I don’t know exactly how many charge cycles, but

they should have over 10,000 charge cycles in a lithium iron phosphate pack if there has not been abuse where temperatures were too high or temperatures were too low during a discharge cycle. And

Kenley Nebeker

Jason just to bring this idea full circle that that’s one of the very unique things about this project. Um, is that, that Levi is really thinking about from the perspective of how do we control the temperature of these batteries? Um, and one of the great advantages of moving to this hybrid, taking marrying the advantages of a gas based motor and the advantages of electric is that you’ve got built into it, a cooling and heat heating system for these batteries, uh, to help keep them

at the, at the proper temperature. So you do get the most out of that life cycle. And that’s, that’s, I don’t think anybody else currently in the market or merging into the market is really thinking of it from that perspective. One of the things that really makes Levi and his and his leadership on this project very unique,

Jason Spiess

interesting about the temperature and, and some of those different things, are there any other idiosyncrasies or variables that are, you know, pretty critical in this project? …

Levi Perkins

I don’t think so. I think that just the, so choosing the motor, So Jason if you can think about this just a little bit and our, our listeners if the truck. So our current diesel engines usually produce if it was a 14 liter engine, like the larger class eight engines that are 12 to 14 liters in displacement, They’re reciprocating piston engine.

Usually there’s 1652 2050 ft pounds of torque. So they and and with that that that’s at the crank, that’s at the flywheel, so at the crankshaft. Now we have to couple that power and send it down the drive line and every time 100% of the time that will be pushed through a transmission and the transmission will have, if it’s let’s just say it’s a straight 10 speed because that’s popular.

It could be a 13 or an 18 speed, but 10 speed transmissions, they usually have an 8 to 1 reduction low gear and then from first gear or low all the way up to 10th, those are all reduction gears. And as soon as you get to 10th gear, it could be direct in 10th, but it could also be an over driven 10th gear where it have a percentage of it that was over driven.

But let’s just say 10th is direct. So if it’s 2000 ft pounds of torque, But your very lowest year is an 8-1 reduction and all of a sudden coming out the back of the transmission, we have 16,000 ft pounds of torque because we reduced it by eight times. But we compounded the torque that many times. So now there’s 16,000 ft pounds coming through the drive line and then our differential is a 4 to 1 reduction.

Well now we compound it four more times. So you can see that the torque is really amplified at the axle shafts, in a conventional semi truck or tractor set up on the road. A class eight truck where the electric, they make a lot of torque at low rpm. But the thing that I see they’re just not utilizing transmissions, it reduces the efficiency, you lose, you use way more amps.

So Kenley and I designed this project where we want to have at least a two speed. So it’s got some reduction. And then as soon as you’re moving down the road, probably in the 38 to 40 42 mile an hour range, you could shift into direct And you could pull a really heavy load and low and then you could move 75 or 80 whatever the speed limit is for the classic trucks, you could go that fast in direct and not consume a lot of amperage.

And, and Tesla has a similar version. They actually have four motors, one at each corner that they’re utilizing, that are very small motors. They’re actually motors out of there. The test of plaid car that, and then they’ll use a two speed gearbox at each corner or each drive axle corner, they’ll have a two speed box. It seems complicated. It’s not traditional. I don’t, they need, they’ll have to have a network of mechanics that know how to work on it.

And uh, we’re more so trying to utilize technology that we’ve had for a while and then just put a motor in front of the differentials and uh lots of different options there. I like the idea of just having a motor and drive lines and figure box outside of conventional axles so they can still be worked on the trucks stop and our truck should excuse me and uh most mechanics or technicians that understand how to work on it, …

Jason Spiess

Just taking a look at the clock here and I see we’ve got about five minutes left and I know we wanted to talk a little bit about transmission and that might be for a different day. I’m kind of curious about just how this is going to integrate into the grid because when we’re talking about uh, you know, we’ve got 100 and 20,000 charging stations now globally.

But when I think of like, yeah, I was just looking online as of 2012 or 2020 and and there’s like 80,000 that are a little bit more higher and or something like that. And so, you know, but when I think of semis, you know, they talked about building semis their own highway back when George sr I think was President, they wanted to have like a superhighway down I 29 from Winnipeg down to Houston.

And so yeah, I mean so semis and you know any sort of transportation logistical supply chain having their own charging station specifically isn’t out of line. Um So I’m I’m more curious about the integration part. Do you see this happening seamlessly or do you think there’ll be a little bit of a hiccup in the first couple of years? …

Levi Perkins

Yeah I think it just depends on how many consumers or fleets by into the all electric uh the all electric semi trucks. I if it’s class class eight and it’s OTR over the road or long haul I don’t think it’ll happen for a while and I it’d be great if it could I just don’t foresee it it it you know I think one thing we talked about in the past was just the number of trucks that are on the freeways right now that are over the road or running coast to coast or locally.

There’s there’s enough of them that you know within it in the Magic Valley where I live there’s so many different truck stops that are along this highway or the corridor there each one of them. I just think of one like a pilot or a loves or a flying J. Or one of these popular truck stops at any given time you can go there if I went there tonight there would be close to 100 semi trucks and trailers parked because there’s drivers that have hit their D.

- T. Period of time that they can drive and now they have bunk time. So if they’re in their bunk eight hours and they’re pulled over at a truck stop which is what they’re designed for. That would be the ideal time for them to charge. And I just don’t think our infrastructure at all right now could handle 100 trucks and every truck stop or even say it was only 50 trucks Charging and pulling in one night.

They’re trying to charge a bank of batteries that would have between 600 to 1000 kilowatt hours and just put in perspective. And again I know we talked about this before but a household of four usually utilizes somewhere between 450 to 600 kilowatt hours in a one month or a 30 day period. So in one night we’re trying to charge one truck Enough power into what similar to a family of four would use in a month. And if we had 50 of them and every one of these trucks, officers around the

country, wow, can you imagine that our grid has to change. I think that’s why kindly and I pushed so hard to have this be a hybrid with not only a range extension device but a device on it, the you know, a low emission piston engine that could actually charge the battery without having to plug into the grid but if you had a grid available and it was it was there, then you could utilize it. So you could do one or the other.

Jason Spiess

Well, as we kind of wrap up your Kenley, any final thoughts this week, as we talk about e V engines, I know you’ve actually been a E V car owner in the past. So any thoughts on something along this

Kenley Nebeker

lines in response to your, to your question? I think that, um, I’ve been a hybrid owner uh, multiple times and I can tell you that it really appeals to me because it truly does marry the best of both worlds and gives you as a driver flexibility. You’re not completely relying upon the grid. Uh, you’re not completely worried about how far you can go because you have that gas in there that if needed, it can kick it on And can, can really extend your range.

And so all that range anxiety that so many people are going through that have switched over to the complete electric vehicles. Um, you know, those people that only drive 16 miles a day, they’re fine, you know, they’ll, they’ll be just fine. But anybody that’s driving, you know, 100 304 100 that you’re gonna miles a day, you’re going to experience range anxiety and so, um, it’s, it’s, uh, this hybrid project, as Levi said, we’ve

pushed hard for this idea because we want to, to eliminate a lot of those issues and, and find a way to show that if you marry the technologies, you get something even better.

Jason Spiess

Alright. Levi anything in closing,

Levi Perkins

I think that’s great, appreciate the time. Today, Jason. It’s exciting. There’s new frontier, I think with all of this and hopefully it’s going in the right direction. I like the direction it’s going now and see what happens. We’re getting closer on the project, so I’m glad we got to keep in touch with you on it.

Click on picture for America’s Crate! Check out these Amazing American Environmental Entrepreneurs! Don’t forget that the promo code OTIS unlocks big big savings!

Submit your Article Ideas to The Crude Life! Email studio@thecrudelife.com

About The Crude Life

Award winning interviewer and broadcast journalist Jason Spiess and Content Correspondents engage with the industry’s best thinkers, writers, politicians, business leaders, scientists, entertainers, community leaders, cafe owners and other newsmakers in one-on-one interviews and round table discussions.

The Crude Life has been broadcasting on radio stations since 2012 and posts all updates and interviews on The Crude Life Social Media Network.

Everyday your story is being told by someone. Who is telling your story? Who are you telling your story to?

#thecrudelife promotes a culture of inclusion and respect through interviews, content creation, live events and partnerships that educate, enrich, and empower people to create a positive social environment for all, regardless of age, race, religion, sexual orientation, or physical or intellectual ability.

Sponsors, Music and Other Show Notes

Studio Sponsor: The Industrial Forest

The Industrial Forest is a network of environmentally minded and socially conscious businesses that are using industrial innovations to build a network of sustainable forests across the United States.

Weekly Sponsor: Stephen Heins, The Practical Environmentalist

Historically, Heins has been a writer on subjects ranging from broadband and the US electricity grid, to environmental, energy and regulatory topics.

Heins is also a vocal advocate of the Internet of Everything, free trade, and global issues affecting the third of our planet that still lives in abject poverty.

Heins is troubled by the Carbon Tax, Cap & Trade, Carbon Offsets and Carbon Credits, because he questions their efficacy in solving the climate problem, are too gamable by rent seekers, and are fraught with unreliable accounting.

Heins worries that climate and other environmental reporting in the US and Europe has become too politicized, ignores the essential role carbon-based energy continues to play in the lives of billions, demonizes the promise and practicality of Nuclear Energy and cheerleads for renewable energy sources that cannot solve the real world problems of scarcity and poverty.

Look at what’s happened to me.

I can’t believe it myself.

Suddenly I’m down at the bottom of the world.

It should have been somebody else

Believe it or not, I’m walking on air.

I never thought I could feel so free-e-e.

Barterin’ away with some wings at the fair

Who could it be?

Believe it or not it’s just me

The Last American Entrepreneur

Click here of The Last American Entrepreneur’s website

Studio Email and Inbox Sponsor: The Carbon Patch Kids

The Carbon Patch Kids are a Content Story Series targeted for Children of All Ages! In the world of the Carbon Patch Kids , all life matters and has a purpose. Even the bugs, slugs, weeds and voles.

The Carbon Patch Kids love adventures and playing together. This interaction often finds them encountering emotional experiences that can leave them confused, scared or even too excited to think clearly!

Often times, with the help of their companions, the Carbon Patch Kids can reach a solution to their struggle. Sometimes the Carbon Patch Kids have to reach down deep inside and believe in their own special gift in order to grow.

The caretakers of Carbon Patch Kids do their best to plant seeds in each of the Carbon Patch Kids so they can approach life’s problems with a non-aggressive, peaceful and neighborly solution.

Carbon Patch Kids live, work and play in The Industrial Forest.

Click here for The CarbonPatchKids’ website

Featured Music: Alma Cook

Click here for Alma Cook’s music website

Click here for Alma Cook’s day job – Cook Compliance Solutions

For guest, band or show topic requests, email studio@thecrudelife.com

Spread the word. Support the industry. Share the energy.